What is the Importance of Sieve Analysis?

December 22nd, 2023 | 2 min. read

Sieve analysis is to determine the gradation of particles within a sample to confirm compliance with design standards. The size of your project and site will determine how big or small the testing sample will be.

This test is a pivotal technique for characterizing the particle size distribution of your materials and understanding the results will ensure complete quality control of your project.

Why is sieve analysis important for my project?

The following are four main reasons for the importance of sieve analysis.

- Material Classification

- Quality Control

- Understanding Particle Distribution

- Material Research

Does Legacy Engineering do sieve analysis and testing?

Yes. Our laboratory has extensive experience with sieve analysis, also referred to as gradation testing.

The overall gist of the analysis is as follows:

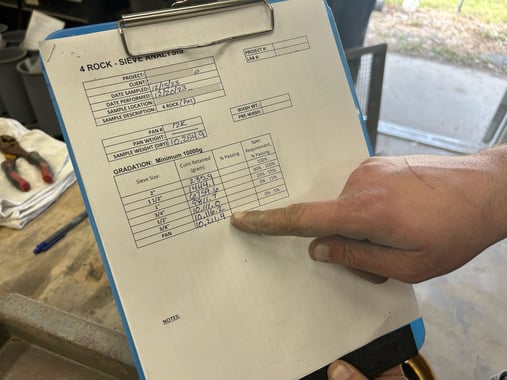

A sample of material is collected from the site and returned to our laboratory. Sample size highly depends on project specifications. The sample size for this particular project was about 10,000 grams.

The sample is poured into a sieve shaker that holds six individual sieve sleeves. As the material falls through each sleeve, it is separated and disturbed by size; the biggest materials on top and the smallest at the bottom.

Once the materials are evenly distributed throughout the sleeves, the shaker is turned on and covered for ten minutes to fully portion out based on size.

After the ten minutes conclude, the first sleeve is taken out, weighed, and the weight is recorded. Each project has a different measurement sheet depending on the type of sample material.

Each sleeve is taken out and the above step is repeated until all six sleeves have been weighed and recorded. Some projects require more than six sieves if the specifications note for a larger sample.

Once every sleeve has been recorded, the final weight should reflect the initial sample size but there may be lost particles due to the shaker distribution method. After the final weight is recorded, the results are converted into percentages and either pass or fail based on project specifications.

Sieve analysis, a cornerstone of quality control in construction, holds immense importance for your project's success. It aids in material classification, ensures quality control, provides insights into particle distribution, and supports ongoing material research. At Legacy Engineering, our laboratory conducts thorough sieve analysis, meticulously following standardized procedures to accurately assess material gradation. With our precise methods and attention to detail, we guarantee comprehensive results that meet or exceed project specifications.

Sieve analysis is a simple quality assurance test to characterize the materials at your site. Ensuring that your construction materials meet specified standards is crucial for the durability and longevity of said materials. If you’d like to schedule your sieve analysis now, please email scheduling@legacyengineering.com.

Moreover, if you’d like to explore more of Legacy’s material testing content and offerings, please click here to be redirected to our materials testing blogs that feature photos and videos of our services.

Topics: